Our most recent printed photovoltaics paper, which was published in Sustainable Energy and Fuels, looks at using a roll-to-roll (R2R) fabrication method for slot-die coated Perovskite Solar Cells (PCSs). The extensive 50-page document is the most descriptive paper of its kind and will influence solar cell research across the globe.

Here, SPECIFIC researcher and one of the paper’s authors, Rahul Patidar, discusses the processes and research that led to the paper being published.

A newcomer to the photovoltaic industry, PSCs have gathered remarkable attention from researchers around the globe. With efficiency reaching similar to that of the current market leader, silicon photovoltaics (PV), attention has been diverted towards upscaling PSCs.

Contrary to silicon PV, which requires high temperature and high vacuum depositions, PSCs can be solution-processed at a low temperature, which significantly reduces the manufacturing cost. Low temperature processing makes it possible to use plastic substrates to make flexible solar cells. And the ability to solution process provides the opportunity for a number of well-developed printing and coating techniques:

- Screen printing

- Inkjet printing

- Gravure printing

- Slot-die coating

- Spray coating

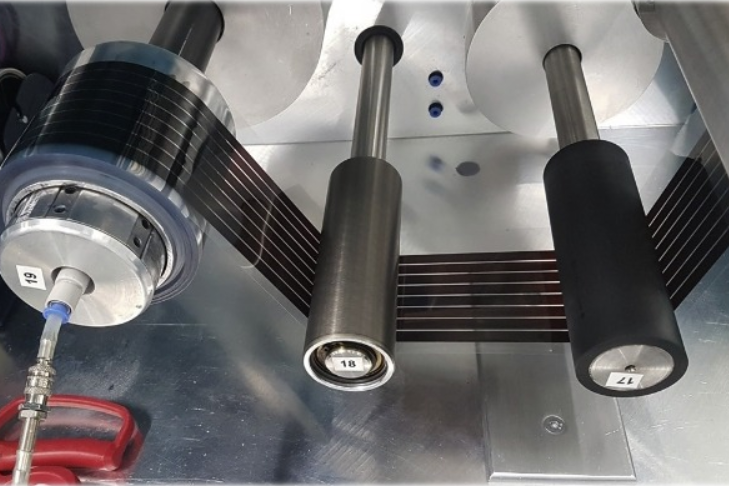

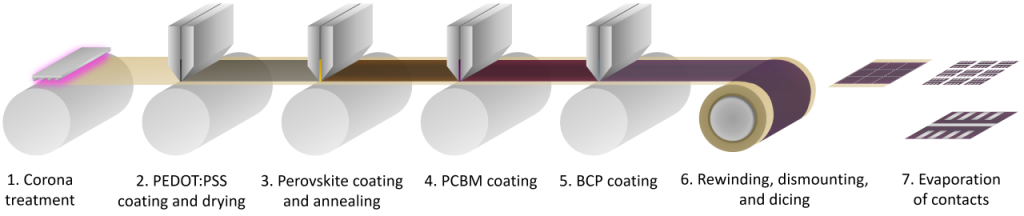

Combining both of these advantages, we can use roll-to-roll manufacturing for PSCs.

We used slot-die coating as it provides number of advantages over the alternatives. It is a pre-metred technique, which means we can control the wet film thickness before coating. It is also highly efficient in material usage, with minimal loss of material compared with spray coating or screen printing.

Another issue that arose in this work was the use of toxic solvents. In the UK, the air exposure of toxic solvents in the workplace is quantified by workplace exposure limit (WEL), which is monitored and regulated by the Health and Safety Executive (HSE). WEL is calculated from the time-weighted average (TWA) of the exposure time. Typical solvents used in fabrication of PSCs are:

- dimethyl formamide (DMF), which as a WEL of 5PPM

- N-Methyl-2-pyrrolidone (NMP), which has a WEL of 1PPM 8-hour TWA

Using these solvents at an industrial scale requires a lot of air handling to stay under those limits, which can incur significant and unnecessary expenses.

For this reason, we used an acetonitrile-based system (WEL is 40 PPM 8-hour TWA), which was first developed by Oxford University. This system has a higher WEL and has a rheological advantage over DMF and NMP due to low viscosity and low surface tension. This results in better coatings.

Along with this, we introduced a ternary blend of high workplace exposure limit solvents (WEL > 50PPM 8-hour TWA), replacing chlorobenzene (WEL 1PPM 8-hour TWA) for the deposition of hole transport material. Our PSCs gave the stable power output of 12.2%, which is the highest efficiency reported for four layers of roll-to-roll printed PSCs.

A complete solar cell for a chosen architecture requires coating 5 layers. Fully printed solar cells would ideally require using slot-die coating for all five layers. But in this case, we coated four layers using slot-die coating and the top contact was put on using thermal evaporation. Why is this? We’re still looking into how to slot-die top contact without destroying any layers underneath. By solving this, we can manufacture a fully roll-to-roll printed PSC.

With thanks to the paper’s co-authors:

Dr Daniel Burkitt, Rahul Patidar, Dr Peter Greenwood, Dr Katherine Hooper, Dr James McGettrick, Dr Stoichko Dmitrov, Matteo Colombo, Dr Vasil Stoichkov, David Richards, Dr David Beynon, Dr Matthew L. Davies, Prof. Trystan M. Watson