Case Study: Capturing Waste Heat From Data Processors (THermify)

Overview

SPECIFIC offers companies with innovative, low-carbon technologies valuable insight and performance data to improve their existing products or processes.

Thermify are developing a technology to capture waste heat from data processors and use it to warm homes and heat hot water. Cloud computing generates heat as a by-product, which means even more electricity is needed to extract and vent the waste heat into the atmosphere.

By creating a secure network of small, but powerful, data centres to replace gas boilers in people’s homes, Thermify aim to use the energy needed for cloud computing twice. Their data centres will provide a service for cloud-based clients to perform encrypted computational tasks, while using the heat from the server cabinet to provide affordable, more environmentally-friendly, heating.

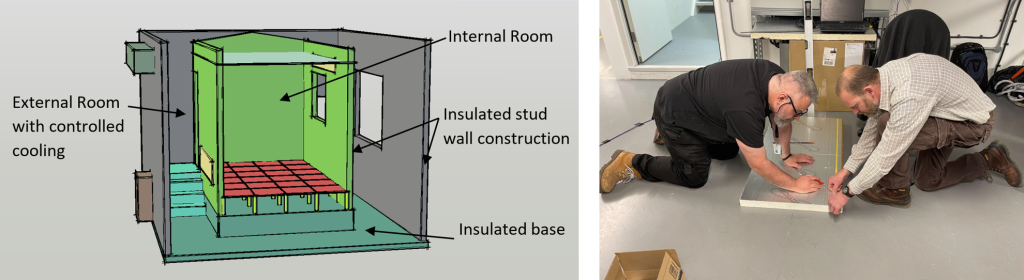

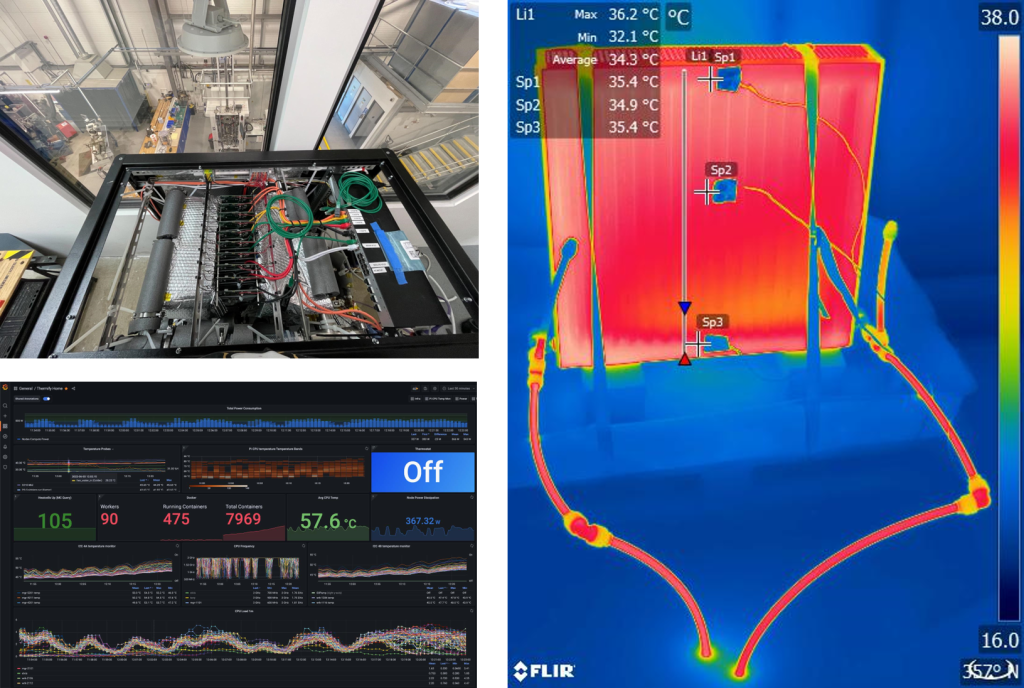

Over a period of two weeks, Thermify installed a half-size server rack equipped with their patented heat transfer technology in SPECIFIC’s climatically controlled room in the Pilot Manufacturing and Research Centre (PMRC). The server cabinet was connected to a conventional water-filled radiator via a heat exchanger, with control and monitoring equipment provided and installed by Thermify. Temperature data from fixed locations throughout the climatically controlled room was logged by SPECIFIC whilst maintaining the external room temperature. Thermify monitored the energy input into the server and heat output from the server and radiator. SPECIFIC also provided a thermographic assessment of the test equipment in use.

Project partners: Thermify

Aims

- Refine and validate platform observability

- Determine steady state performance in a controlled environment

- Observe extended steady state performance

- Establish true hands-off monitoring and management procedures

- Establish baseline performance

Impact

- Successfully installed and tested waste heat capture system in a controlled environment to establish baseline performance

- Acquired data on steady state performance, including temperature, energy input, and heat output

- Established true hands-off monitoring and management procedures

- Identified need for broader and calibrated/validated sensor data in experimental systems

Figure 1. (left) Diagram showing climatically controlled room. (right) Preparing the climatically controlled room for the waste heat capture system.

Figure 2. (top left) Thermify’s waste heat capture system. (bottom left) Example system monitoring dashboard. (right) Thermographic image of the radiator in operation.