Steel is the core product in manufacturing, national infrastructure and high-tech 21st century industries such as electric vehicles and Active Buildings. It is the most widely used material in the world, so in order to create a more sustainable future, we must deliver innovation quickly.

However, despite its wide range of uses, steel and other metals are susceptible to corrosion – which accounts for ~3% of the global GDP each year. A key protection mechanism is to ‘galvanise’ the metals – this process provides barrier protection for the base steel and when scratched or damaged, it sacrificially protects the steel underneath and self-heals. Without galvanising, our buildings and infrastructure would prematurely fail, with costly and sometimes dangerous consequences.

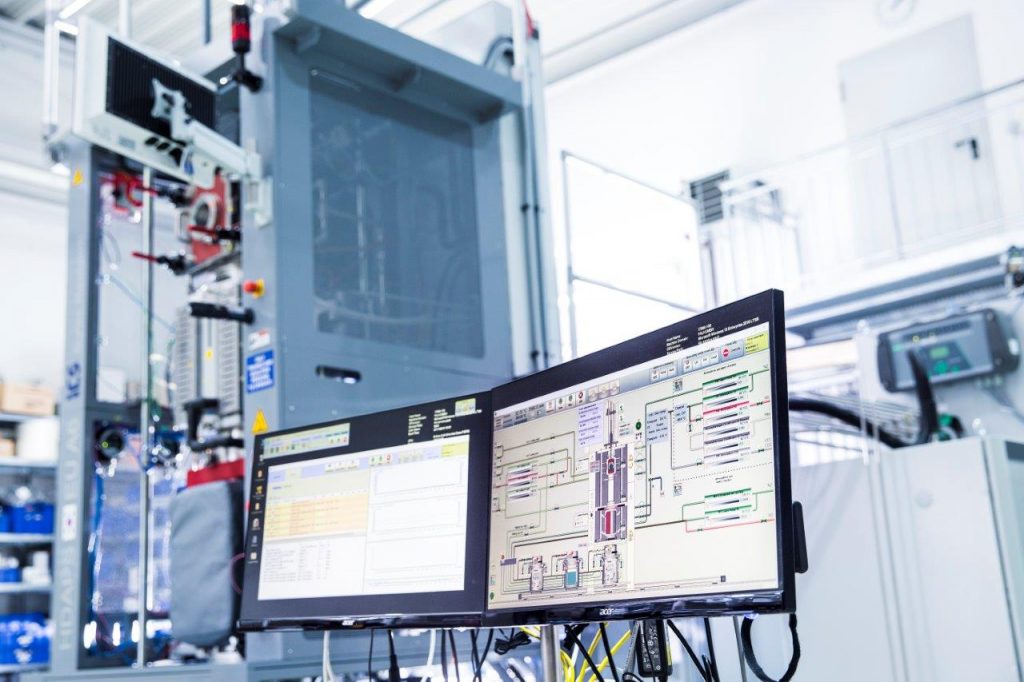

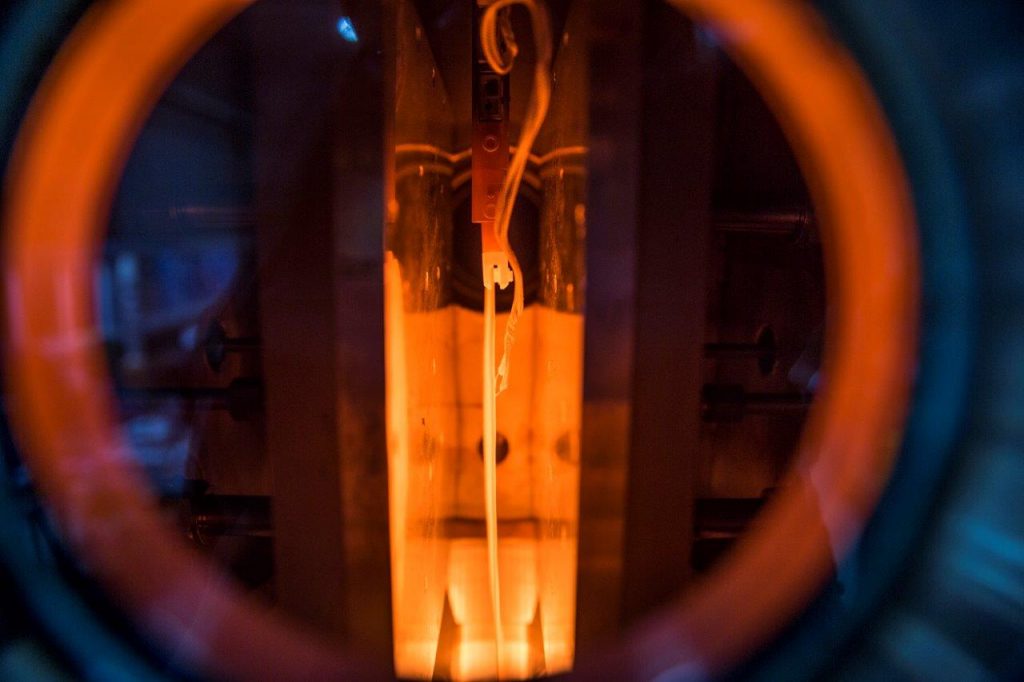

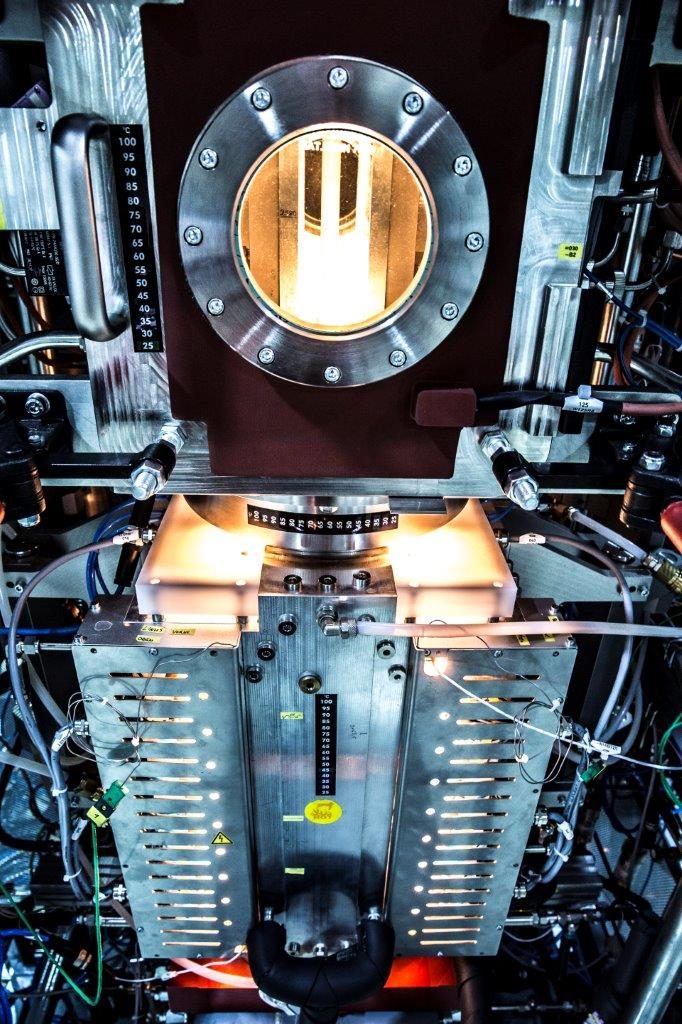

In order to advance galvanising alloys for 21st century industries, SPECIFIC and The Materials and Manufacturing Academy (M2A) have added a £1.3m piece of kit to the Pilot Resource Manufacturing Centre – The Hot Dip Process Simulator (HDPS). The advanced equipment will allow laboratory scale simulations of the continuous galvanising process that occur in industrial production lines. The ultimate aim is for process and product development through varying substrates, bath compositions and hot dipping parameters. Then, the results obtained by these simulations are transferred to the production process of real continuous galvanizing lines.

One of SPECIFIC’s key aims is to enable rapid commercialization with industry, so the Pilot Manufacturing Research Centre is the perfect location for this new equipment. By bringing together academics and industry partners – steel alloys can be tested to enhance their material properties, supporting innovation in steel and help ensure our steel industry remains at the cutting edge of innovation.

Multiple projects within the University will be using the HDPS, covering areas such as strength, electrical and mechanical properties, as well as durability and resistance to corrosion. SUSTAIN lead a grand challenge research project looking into carbon neutral steel and ironmaking and smart steel processing. M2A recruit industry-sponsored doctorate and PhD students that focus on industrial research projects in materials and manufacturing. The University is also home to the ‘Steel and Metals Institute’ (SAMI) – an open access centre delivering innovation through industry and research partnerships, Prosperity project which implements rapid alloy prototyping using state-of-the-art imaging, and of course, SPECIFIC, who specialise in functional coatings for photovoltaics, batteries (and more) to develop Active Buildings.

The installation involved working with many specialist suppliers and contractors for what was a one-off bespoke installation. The final 3 weeks of installation involved SPECIFIC staff working closely with the Engineers from Surtec in Germany, the experience and knowledge shared between both Surtec and SPECIFIC staff proved to be invaluable in getting to the HDPS fully operational.

The £1.3M equipment was funded by Higher Education Funding Council for Wales (HECFW) to support Swansea Universities grant applications to UK Research and Innovation (UKRI). The capital investment by HECFW helped the University win multiple bids which amount to more £47million in additional research funding.

Professor David Penney, Director of Swansea University’s Materials and Manufacturing Academy commented:

“We are really excited to have this unique and powerful piece of equipment here at Swansea University’s Pilot Manufacturing Research Centre. It will allow us to take the new complex galvanising alloys developed in projects such as Prosperity, SPECIFIC and SUSTAIN and prove the industrial process of annealing and galvanising, as well as their resistance to corrosion. This means we can develop new steels for cars, building, infrastructure and household goods – keeping our UK steel globally competitive and at the cutting-edge of innovation”