Since being built, the Active Classroom has proved the Active Buildings’ generate-store-release concept, tested ten new-to-market products for companies, hosted countless events and lectures, acted as a key tour ‘stop-off’ for Government ministers and students alike, and finally, won five awards in the process!

Boasting these great credentials, it’s easy to forget that the building is constantly evolving to improve its functionality, and to test and develop new technologies and approaches. Having been running for 3 years, the Energy Storage System (ESS) is now being renewed to meet fresh challenges such as new electric vehicle charging ports, Demand Side Response projects, and energy sharing with its sister building, The Active Office.

The new ESS consists of twelve 10 kWh Redflow batteries (ZBM2) – a modular zinc-bromine flow battery designed from the ground up for building integration. The 120 kWh array was carefully selected by SPECIFIC’S Smart Systems Technology Transfer Fellow, Tom Griffiths, because of their ability to deliver 100% of the rated system energy every day, without degradation in capacity over a long – 10 year – life. “These characteristics were crucial considerations for us as our application involves repeated, prolonged charge and discharge durations depending on EV charger utilisation and demand side response, making Redflow’s flow battery the ideal fit for our requirements in comparison to more conventional lead-acid or lithium alternatives.”

Redflow Batteries

Batteries Close-Up

The Active Classroom

Following their long journey from Redflow’s manufacturing plant in Thailand, through the Suez Canal and Mediterranean Sea, the batteries arrived safely in the UK and are now in place at the Active Classroom. The UK’s first installation of Redflow’s ZBM2 batteries will be completed by local experts PhotonPM and Off Grid Engineering Ltd. The Redflow battery system will deliver nearly three times the energy storage capacity of the previously installed Aquion Batteries in a real use scenario, supplying nearly four times as much instantaneous power. Not only will this surpass the needs of the classroom, it will allow us to use the building and EV charging as a controllable grid asset rather than simply a consumer, and implement Demand Side Response as well as scheduled export strategies to lower grid carbon intensity and provide grid balancing.

Redflow CEO & Managing Director Tim Harris said “Redflow is delighted that Swansea University selected our technology. This project with its dual renewable generation sources will be a benchmark for flow-battery minigrids. This is an emerging segment that Redflow is focussed upon, having recently deployed some PV-only minigrids in the agricultural sector in Australia.”

Additional Information:

How does a flow battery work?

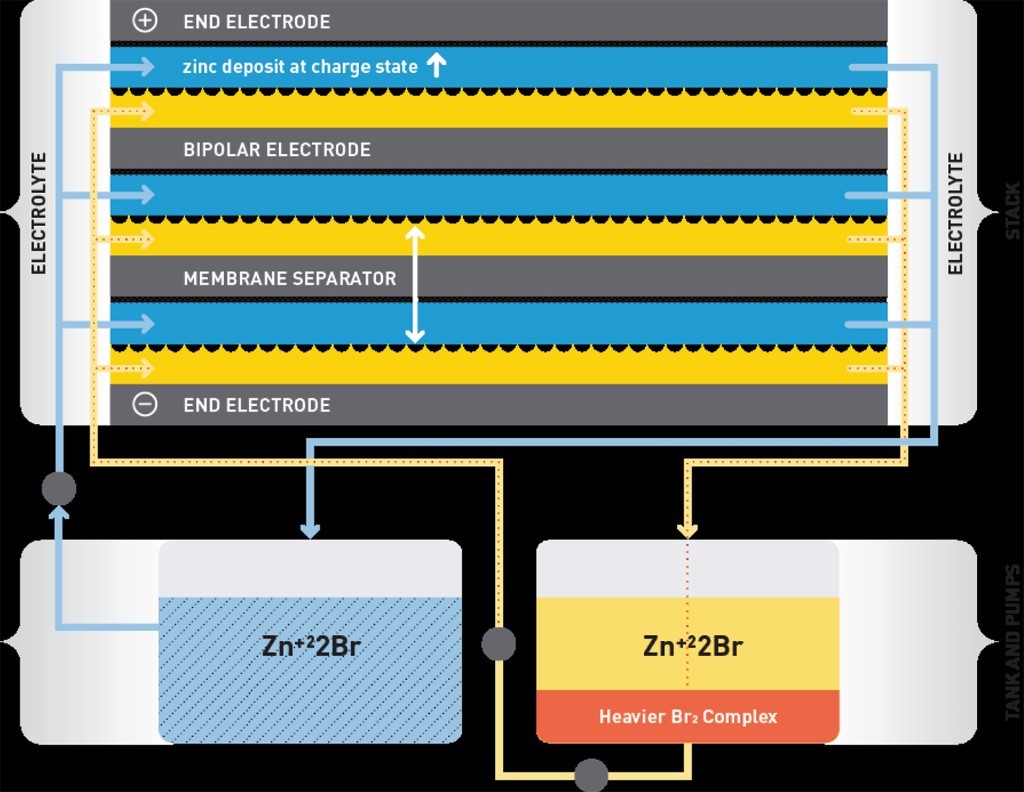

Each battery contains about 100 litres of a water-based zinc bromide salt solution that circulates in two separate hydraulic circuits. When charging, zinc is extracted from the zinc bromide solution and stored on a plastic membrane. During discharge, zinc is released back to the solution. A major benefit of this process is that it causes no degradation to the battery when the zinc is removed at the end of each cycle, giving it a sustained, long-life energy storage capacity.

What are the batteries made from?

The Redflow battery is constructed from easily recyclable materials, such as polyethylene plastic, aluminium and galvanised bolts. The largest, and most expensive, element of the Redflow battery is the 100 litres of water-based zinc bromide electrolyte, which weighs about 140 kg. The beauty of this electrolyte is that, unlike lithium, it is cost-effective and practical to reuse.