CASE STUDY:

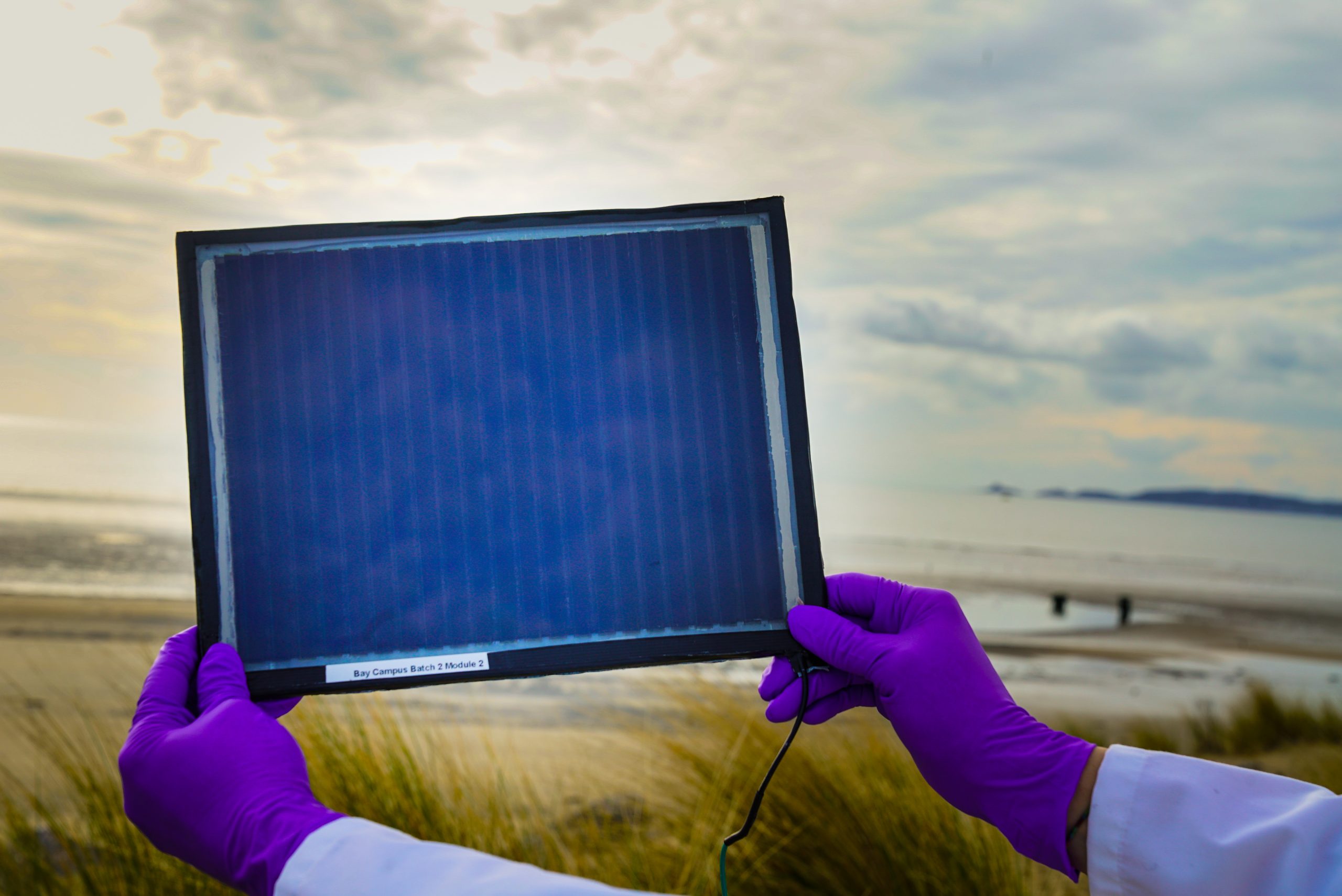

LARGEST FULLY-PRINTED PEROVSKITE MODULE

Overview

Widely hailed as the next big thing in solar technology, third generation perovskite solar cells (PSCs) are flexible and lightweight and can be printed onto glass or metal, making them a solution for application in building integrated photovoltaics (BIPV).

SPECIFIC has world-class facilities that aim to scale-up solar technologies from lab to full-scale, and the scale-up of PSCs are an example of the work being undertaken by our researchers. PSCs also work well in low light conditions, such as we have in the UK. One of the main benefits of this technology will be low cost energy generation to satisfy the low-carbon economy according to the UNFCCC agreement to reduce the carbon emission by 2050.

Aim

For perovskite cells to become commercially viable, they need to be cheap and efficient to manufacture at scale. SPECIFIC’s creation of academia’s largest fully-printed series-connected perovskite module has a 198cm2 active area and over 6.3% efficiency.

The low light performance has 11% and 18% PCE achieved respectively at 200 and 1000 lux under fluorescent lighting (usual indoor illumination level in living rooms and hypermarkets, respectively).

This can also be manufactured at a low-capital cost, which could enable production by any sized company, and be advantageous for large-scale production in developing countries.

Impact