Thermoelectrics can play an important role in our future green energy mix. At present, huge amounts of heat are produced as the by-product of industry. Most of this heat is lost to the atmosphere. At SPECIFIC, we’re looking at ways to capture this waste heat and turn it into electricity. Recent advances in thermoelectric research show devices are rapidly increasing in efficiency. We chatted with Dr Matthew Burton to find out more about his latest review paper on printed thermoelectrics.

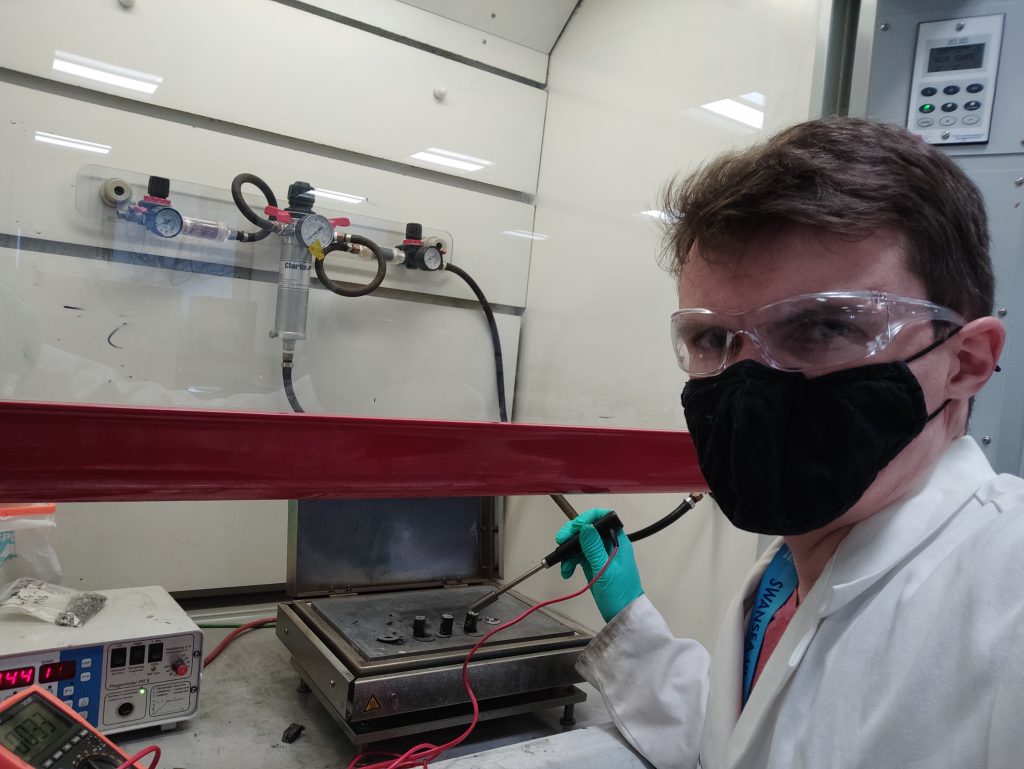

I’m Matthew Burton, I’m a Research Officer here at SPECIFIC and I look at thermoelectric materials. In short, that is turning heat sources into electricity.

1. What is the paper about?

So the name of the paper is Printed Thermoelectrics. It’s a review paper, looking at the literature of printed thermoelectric materials. It covers from the inception of this idea through to modern day usage of the technique.

So when lockdown struck and I wasn’t allowed to do any work in the lab, I thought it was a perfect opportunity to me to summarize in a review paper what the field of printed thermoelectrics is. And it’s massively moved on in the last five years. The advent of being able to 3D print thermoelectric materials has made them far more efficient. And if you look at recent examples of the 3D printed thermoelectric materials, they are now around the 70% efficiency of commercially manufactured materials. If this trajectory was to continue, they will be more efficient than commercially materials fairly soon.

2. How can thermoelectrics help us on our journey towards net zero?

The move to net zero will require a diverse range of green energy sources. Whilst solar and wind are absolutely vital in this, by themselves for the UK to be energy secure, they will not manufacture enough electricity. Therefore, we need a wider range of green technologies and there is a lot of waste heat out there. Especially when you look at things like steelworks and glass manufacturing. And if we can use these thermoelectric generators to harvest some of the waste heat, they can be a vital part of our network grid to allow us to slowly transition towards a net zero society.

3. What are the advantages of printed thermoelectrics?

Cheaper to Manufacture

With printing you don’t have these high temperature, high pressure requirements which allows you to manufacture these materials much more cheaply.

Now this is important because at the moment, thermoelectric generators are very expensive to manufacture, which leads to them being used in very few sources. You can find some niche examples in space, but beyond that they’re not widely adopted. But if we can manufacture them more cheaply, we can therefore put them in waste heat sources like steel or glassworks initially, and therefore they can start generating useful electricity.

Short Investment Payback Period

Recently there was a study of thermoelectric generators in the steelworks and it showed that it takes seven years through current manufacturing techniques for the steel company to recoup their investment. The idea of printed thermoelectrics is therefore to reduce this time drastically, making them far more appealing for use in industry.

Wider Range of Applications

So one of the advantages of printing is the fact you can make custom shaped materials. So at the moment, these high pressure manufacturing techniques result in flat materials, because if you imagine you’re pushing something down with a lot of pressure, ultimately it’s going to form a flat surface at the bottom. Now, in theory, you could try and cut these materials to match curved shapes, but due to the nature of crystal structures as thermoelectric materials, they’re quite brittle materials.

However, if you’re printing materials you don’t have as high pressure requirement, therefore, you can make nice curved shapes. If you think about waste heat sources, they’re most commonly on curved surfaces like pipes. So, if you can only make flat generators, they’re not very useful to align onto the curved shape of a pipe. But with printing, in theory, you can go find your waste heat source, draw it out and then come back and custom make a printed generator just to match that exact geometry. And therefore printed thermoelectrics have a potential for much wider applications than planar typically manufactured ones at the moment.

4. Where could thermoelectrics play a key role producing green electricity?

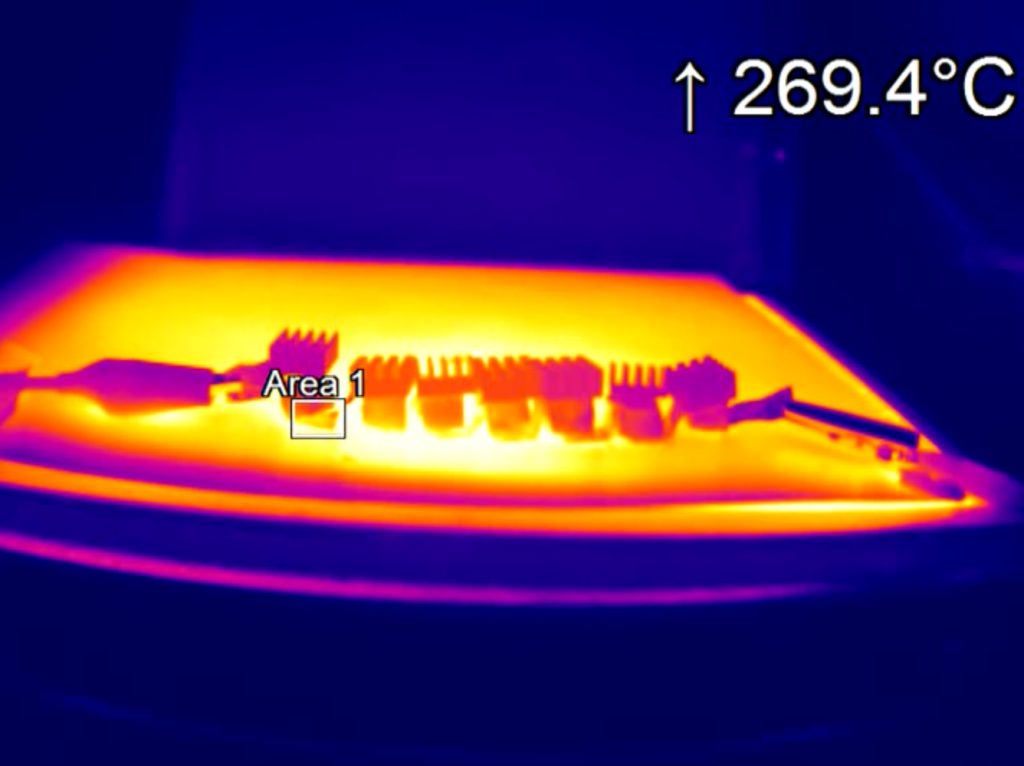

So, one of the key ones to look at the moment will be steelworks, because they generate a lot of waste heat that is vented to atmosphere. These could be used in steelworks to harness some of their waste heat and reduce the steelworks’ demand on the grid or simply just to add some electricity back to the grid.

But it’s not just steelworks where we could use thermoelectric generators. There are plenty of other waste heat generating industries out there, such as glass. Or to a certain degree, the nuclear industry itself. As printed thermoelectrics can evolve in the future, we can hopefully drive down the cost of making thermoelectric generators, we could potentially expand their use into the more domestic setting as well. And therefore, heat pipes that you may have inside your house, eventually may be able to have thermoelectric generators attached to them to generate useful electricity.

Another potential use would also be to make self-powered sensors. So rather than having to have a battery that would endlessly have to get changed or for annoying wires to be used for a sensor to be powered. If in a scenario there is a waste heat source, you could in theory use a thermoelectric generator to power a sensor.

So this has potential uses in steelworks where they want to monitor temperature of devices that have a lot of waste heat, but they don’t want to endlessly change a battery. If you can put thermoelectric generators there, you can have a self-powered sensor that therefore doesn’t need any maintenance at all.

Printed Thermoelectrics has been published in Advanced Materials. The work has been carried out by Swansea University in conjunction with Tata Steel.