Our carbon PV team recently visited Merida, Mexico to deliver a university workshop on screen-printed solar cells, meet with collaborators at Cinvestav and hold discussions with local businesses. Dr Becky Bolton, Dr Sarah-Jane Potts, and Dr Carys Worsley tell us how it went…

Arrival

On April 20th 2023, we arrived in Merida, Mexico after 26 hours of travelling. We checked in at the Gamma Mérida el Castellano around midday following a much-needed breakfast at the adjacent El Salmantino Restaurante. Wasting no time, we headed out to Centro de Estudios de las Americas (CELA) to assist the Cinvestav team in setting up for the following day’s workshop, which was anticipated to be jam-packed with activities.

University Workshop: Manufacture and Characterization of Screen-Printed Carbon Perovskite Solar Cells

Inauguration and talks

The Manufacture and Characterization of Screen-Printed Carbon Perovskite Solar Cells workshop at CELA began with an Inauguration Ceremony to open the day.

We delivered three presentations for the workshop:

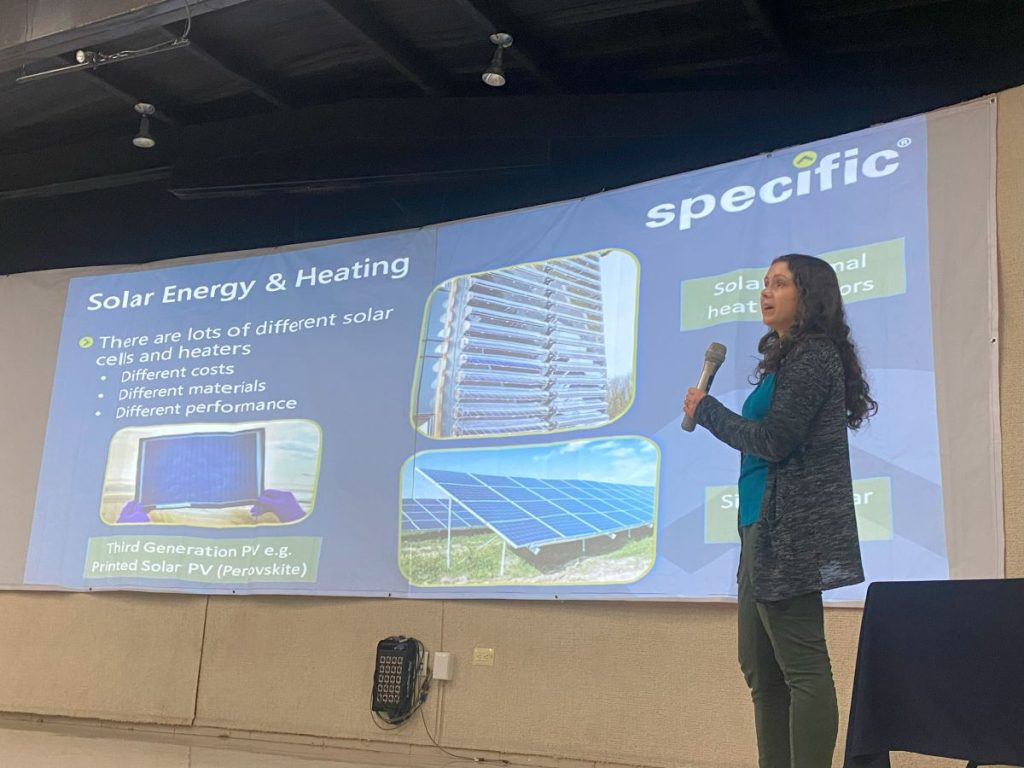

- Sarah-Jane provided a well-structured introduction to SPECIFIC and renewable energy as a goal for the future. She passionately described the simplicity and scalability of screen-printing, and how it can be used to make resistive heating coasters and floor tiles, as well as the perovskite solar panels the students would be making themselves during the workshop. Sarah-Jane’s informal approach allowed the students to get on board with her ideas and inspired much discussion at the end, with students asking many questions, from wearable solar panels to her personal view on climate change and our responsibility for the planet.

- Carys’ talk was highly focused on solar power as a renewable technology and provided an in-depth, but inclusive, explanation of the fundamentals. First capturing the student’s interest with the well-known fact that “every hour enough energy reaches the earth to power the needs of every human being for a year”, Carys then delved into the various commercial solar technologies before introducing the up-and-coming Perovskite based devices. She gave examples of recent successful research conducted by the team at SPECIFIC in collaboration with Cinvestav and provided an honest look into the issues still left to overcome.

- Becky’s talk rounded off the morning with a look into the possible route for commercialisation of the Carbon Perovskite Solar Cell (C-PSC) technology. Starting with breakdown of the C-PSC structure, and a reminder of recent research developments into the fundamental architecture, Becky then took the students step-by-step through a theoretical continuous fabrication line for C-PSC modules. She finished up her talk with the method for measuring the performance of current state-of-the-art C-PSC prototype modules: a weathering station in Port Talbot set up in January 2022 that has been continuously monitoring the panels for over a year. She then introduced the sister-station recently constructed at Cinvestav that the students would be shown later in the day.

Game of Electrons

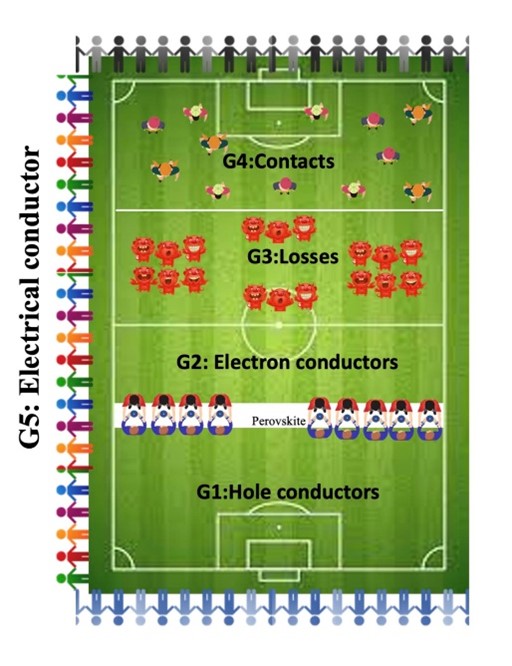

After a morning of solar-inspired talks, we divided the students up into five teams to create a living demonstration of how a perovskite solar cell works, in an activity called “Game of Electrons” designed by the Cinvestav team. Members of the SPECIFIC and Cinvestav teams were assigned as monitors for each of the groups: “Hole Conductors”, “Electron Conductors”, “Losses”, and “Contacts”, with the field set up as above, before giving each member of the “Hole Conductor” team a ball that represents an electron.

The goal of the game is to create the most efficient cell possible by passing the balls (electrons) to the “Electron Conductors”, who try to throw the ball past the “Losses” group to the “Contacts” group on the other side. The “Losses” group try to block these balls and represent the real issues that can limit solar cell performance.

Any balls the “Contact” group catch are given to the “Electrical Conductor” group, who pass them down to a box at the “Hole Conductor” end. The number of balls successfully collected in the box at the end represents the efficiency of the solar cell.

After a fast-paced 10 minutes of electron mayhem, the game ended, and the judge ruled that the cell efficiency was “measured” at 2%: a divisive win by the “Losses” team who demonstrated only too well how losses in a perovskite cell can significantly limit function. Luckily, our perovskite C-PSCs are much better than this human solar cell!

Practical Workshop: Screen-printing the Triple Stack

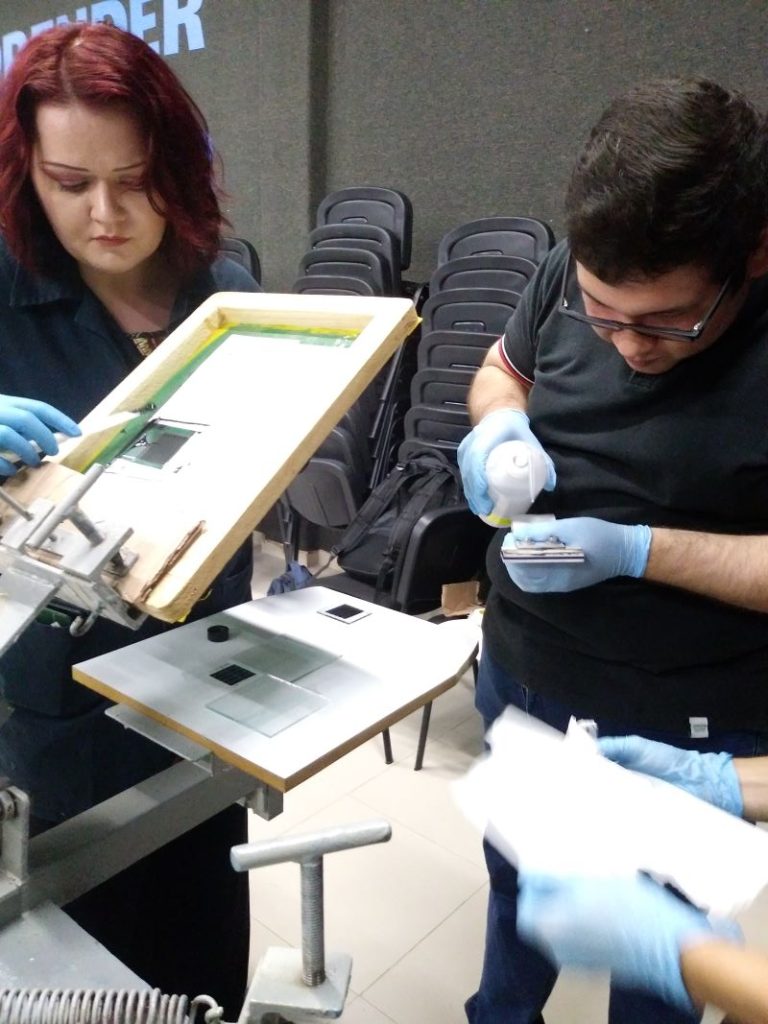

After this, everybody reconvened in the auditorium to commence the next stage of the workshop: hands on screen-printing of C-PSC modules. Each student was given a 5cm x 5cm piece of pre-scribed glass to manually print their own solar module. We set up three stations, each with three manual screen-printing areas (one for each layer of the cell), a hot plate for drying each layer, inks, squeegees, substrates, and PPE.

This allowed the students to make their own piece of solar technology, gain first-hand experience in screen-printing, and demonstrate how simple C-PSCs can be to make. This showcases one of the main advantages of C-PSCs, which have been earmarked as the frontrunners for perovskite commercialisation because they are made using screen-printing: a simple, inexpensive process that is typically used for making t-shirt designs. This makes them relatively easy to scale-up and massively reduces the likely cost of a potential C-PSC factory. Compared to the factories used to make wafers for silicon solar panels, which cost billions and use complex and energy intense fabrication methods, these cells would be much cheaper and easier to produce.

The first layer to be deposited was the mesoscopic TiO2 layer; members of SPECIFIC and Cinvestav guided the students through the manual screen-printing process and importance of screen alignment with the scribes on the glass. Once the students had printed their TiO2 layers, the substrates were placed on hot plates to dry. During this time, students were instructed on the correct ways to clean their equipment and workspace. The ZrO2 layer was then deposited on top of the TiO2 layer and dried in the same fashion, each student becoming more practised in the process and recognising the importance of carefully aligning the screen to ensure the layers were stacked correctly. By the final carbon layer, the students were well versed in screen-printing and required very little guidance to complete their stack!

Group Rotations: Infiltration Workshop / Solar Scalextric / Rooftop Weathering Station

After lunch the university students were split into 8 groups to rotate between a number of device demonstrators and final C-PSC device fabrication steps: infiltration and conversion, contact application and characterisation.

At the infiltration station, the perovskite light absorber was placed into the printed stacks. Because the modules are mesoporous (each layer has mesoscopic holes, like a tiny sponge), the liquid perovskite solution sinks through all three layers when you drop it onto the module. The modules were then heated and the yellow solution dried to form black perovskite crystals. The students’ modules were infiltrated with a robotic head on an x-y stage, providing a glimpse into how the process might take place at larger scale in a factory. This also made the process easy to do and fun to watch!

At the module demonstration station, three ipad-sized C-PSC modules were set up in series to power a Scalextric car racing kit. The interactive demonstration ran by Kat and Sarah-Jane allowed students to race two cars against each other, powered only by the intense Mexican sun. The hands-on demonstration was met with great enthusiasm and intrigue from the students, resulting in many hours of racing the cars, along with a range of questions on the science and industrial potential of C-PSC modules.

The rooftop weathering station constructed at Cinvestav represents a major milestone for the project. To measure 30cm x 30cm panels produced in Swansea in a hot environment, the Cinvestav team built a sister-station to the outdoor weathering station constructed by the SPECIFIC team in Port Talbot.

This weathering station has been live since 9th March 2023 and has already gathered invaluable information on the C-PSC modules’ performance in the Merida climate. Groups of university students were brought onto the roof to view the weathering station whilst Becky and Bety co-presented the equipment. Becky described the fabrication process for the modules currently under measurement and the importance of comparing their performance in climates as diametrically opposed as Swansea and Merida. Bety followed on by discussing the details of the weathering station, such as the various measurement devices and how the structure itself was fabricated.

Research Discussions and Industrial Seminar

The remainder of the trip to Merida was spent discussing progress in the project and work to do going forward. Prof. Trystan Watson gave a guest presentation at Cinvestav open to all, discussing the importance of green technology and how the project was making progress toward democratised solar power.

Over two days, the Swansea and Cinvestav teams presented their most recent work to each other, offering suggestions and further collaborative opportunities. Additionally, both teams hosted a seminar for two local business: Mantenimiento y Control Electromecánico (a local fabricating business specialised in metals) and T-Bag (a local screen-printing company). The purpose of the industrial seminar was to discuss eventual commercial fabrication of the carbon solar device, which is soon to become a reality.

The visit to Merida was an all-round success; reflecting the immense hard work carried out by both the teams from SPECIFIC and Cinvestav. The teams now continue their journey in the project to ultimately create the solution to low cost and reliable solar power for everyone.

This project was supported by a Royal Society International Collaboration award (ICA\R1\191321) and the British Council Newton Fund Impact Scheme (541128962).