Congratulations to Dr Jenny Baker on winning a £1.2 million EPSRC research grant. The TReFCo project (Thermal Recovery of Functional Coatings) will investigate thermal recycling methods for functional coatings.

It will also develop wavelength sensitive adhesives which will ‘unglue’ when subject to certain types of radiation. The aim of the project is to make the possibility of a truly circular economy one step closer to being a reality. The three-year project starts in April 2022.

Dr Jenny Baker explains why this research is needed:

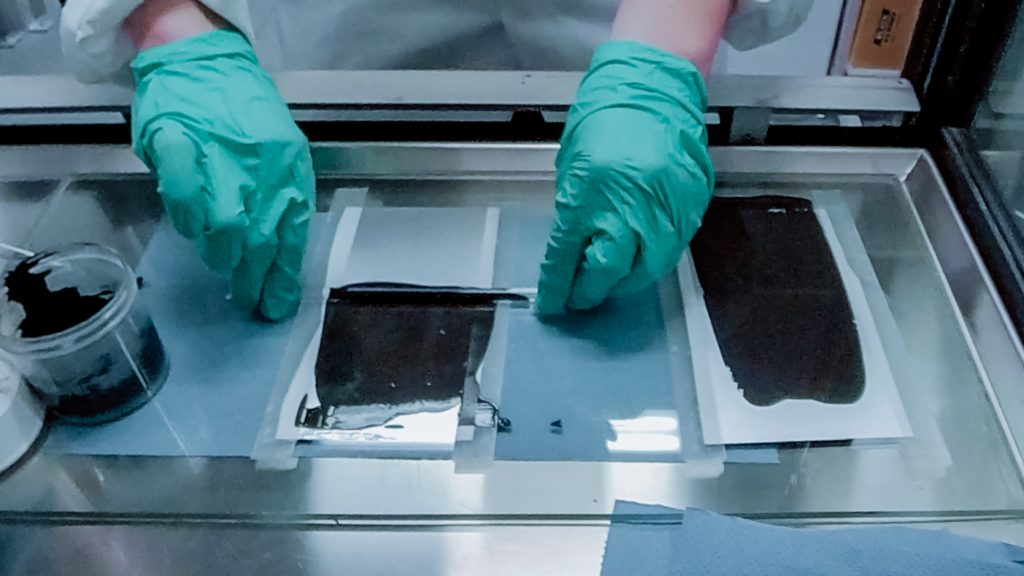

“When devices such as computers, smart phones and batteries are sent for recycling, not all the materials are captured for use in new devices. Specialist coatings are often made with rare and expensive materials to enable our modern electronics to work.

However, these coatings can cause problems when it comes to recycling and the materials are not always recovered but incinerated to produce ‘heat from waste’. This means that the expensive, cleverly engineered coating has been lost and its value not realised.”

What does TReFCo hope to achieve?

TReFCo aims to develop a low-cost method for removing these coatings so that they can be reused to make new devices. This will have multiple benefits. It will mean that valuable raw materials are kept within the supply chain, supporting the UK economy. It will also mean that the materials that they were coated on are cleaner prior to their recycling process ensuring a purer recycled product at a lower cost.

In addition, researchers will undertake a lifecycle analysis. This will ensure they fully understand the environmental costs of producing and recycling materials. They will also identify environmentally damaging areas so they can be avoided. This will be done by material design or by changing the processing methods.

Dr Gavin Harper, from the University of Birmingham, said:

“We are looking at conducting detailed techno-economic comparisons between the TReFCo technology and other recycling technologies that are available. We believe that the TReFCo process could offer many advantages through being a dry, low energy process that will be well suited to some recycling applications.”

Dr. Pete Curran, Head of Materials of Deregallera Ltd commented:

“The key enabling technology required to facilitate mass recycling of battery cells is a low environmental impact process for recovery of the active electrode materials. Recycling end-of-life cells is itself paramount to minimizing the eq-CO2 emissions embodied in our products which is of critical importance to Deregallera and the end users of our battery technology.”

Dr. Kai K.O. Bär, Managing Director of adphos Group added:

“adphos group welcomes the opportunity to support this world leading team in the furtherment of the circular economy and the advancement of Low/No CO2 technologies using adphos’ advanced-NIR.”

The project is a collaboration between led by Dr Jenny Baker, Swansea University partnered with University of Birmingham, Keeling and Walker, Precision Varionic, Deregallera, Tata Steel, adphos Group, Elemental Inks & Chemicals, WRAP and Plug Life Consulting.