We recently celebrated 10 years of our Pilot Manufacturing Resource Centre (PMRC). Based in Baglan, the PMRC is a world-class research and technology facility that acts as a vital stepping stone for progressing renewable technologies from the lab to factory. Looking back over the last decade, our staff have selected 10 of its most memorable moments. Here’s numbers 6 – 10 (go here for part 1).

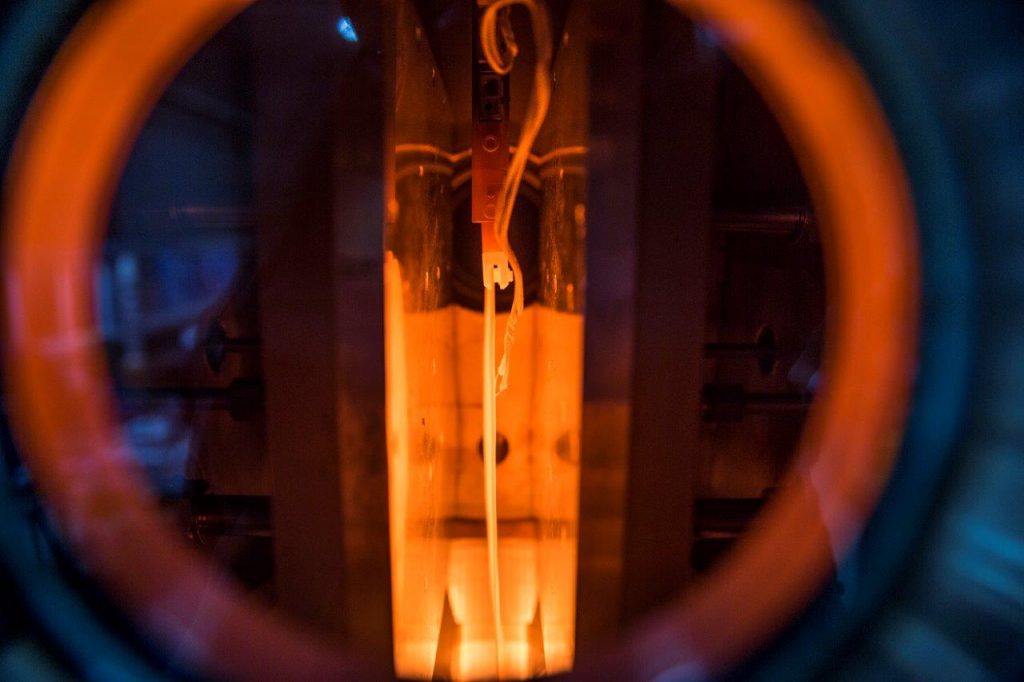

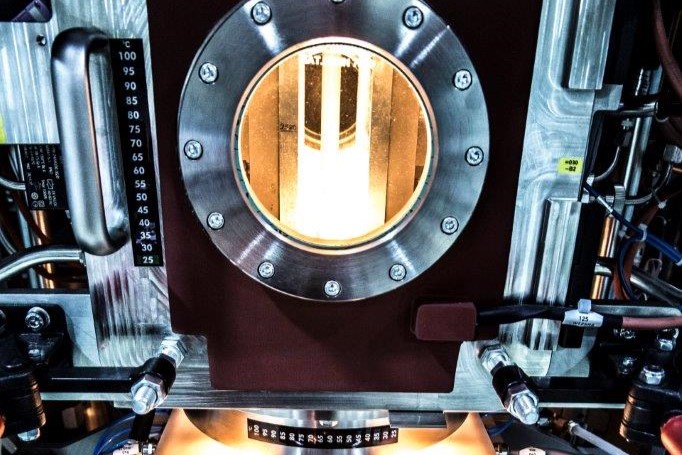

6. Installing the Near Infrared Oven

One of the most remarkable pieces of kit we added to the pilot line was the near infrared (NIR) oven. Using NIR speeds up the curing process quite significantly.

Previously, one of the biggest manufacturing bottlenecks for perovskite solar cells was annealing or curing the perovskite layer, which took up to 90 minutes in the oven at 100°C.

At PMRC, we pioneered the use of near-infrared for a range of drying and curing processes in solar cell manufacture. Astonishingly, using the NIR oven reduced the annealing step from 90 minutes to under 3 seconds.

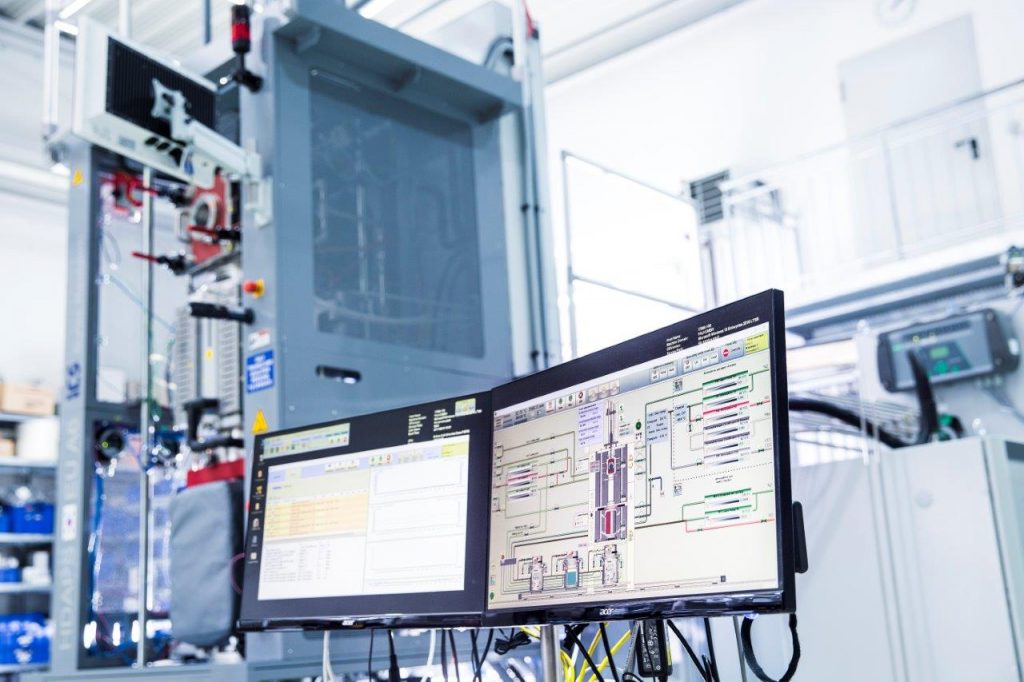

7. Installing the Hot Dip Simulator

Added to the PMRC in 2020, the Hot Dip Simulator (HDS) is a £1.5m investment that allows us to closely replicate a continuous hot dip galvanising line on a much smaller scale. To protect steel and other metals from corrosion they are often galvanised, which provides a protective coating for the base steel. Without galvanising, our buildings, cars and infrastructure would fail prematurely, with costly and sometimes dangerous consequences.

The HDS means we can experiment with novel metallic coatings, heat treat new steels and change process parameters in a controlled fashion. The results can then be transferred to the production process of real continuous galvanising lines, supporting innovation within the steel and metals industry. This is timely since there is a drive to understand how steels made in an electric arc furnace perform in various applications and to invent new, better performing metallic coatings.

Multiple projects at Swansea University have taken advantage of the HDS, including SUSTAIN Steel, M2A, the Prosperity Partnership with Tata Steel, and the Steel and Metals Institute. COATED Engineering Doctorate student Dan Britton has recently been using the HDS to look at varying the chemical composition of Zn-based coatings used in galvanising. By doing this, he can study the effect on corrosion protection and mechanical properties, and make recommendations to industry based on the results.

The HDS has also been used to support research with companies such as Tata in India and SSAB in Finland, allowing researchers to build connections and share knowledge with companies around the world.

When it was first installed, Professor David Penney said:

“We are really excited to have this unique and powerful piece of equipment here at Swansea University’s Pilot Manufacturing Research Centre. It will allow us to take the new complex steel and galvanising alloys developed in projects such as Prosperity, SPECIFIC and SUSTAIN and prove the industrial process of annealing and galvanising, and fully characterise their corrosion resistance. This means we can develop new steels for cars, building, infrastructure and household goods – keeping our UK steel globally competitive and at the cutting-edge of innovation.“

8. Making and Bottling Hand Sanitiser

During the Covid-19 pandemic in 2020, lots of our standard operations had to stop. Instead, the PMRC was used to make hand sanitiser. Over 30 volunteers from SPECIFIC and elsewhere in Swansea University made and bottled 5000L of hand sanitiser a week to help the NHS.

The sanitiser, which meets the standard set by the World Health Organisation, was made using ethanol provided by Coles Brewery, one of the largest distillers in Wales.

To speed up the process, the team devised a multi-head bottling apparatus which can fill a 5L bottle in 20 seconds rather than 60 seconds.

The sanitiser was also used by care home and frontline housing teams and 12 local schools.

At the time, Professor Dave Worsley said:

“We’ve got a rich heritage of manufacturing in South Wales, and as a University, we were eager to adapt our skills and facilities to help protect our NHS heroes. The long-term supply chain will replenish stock eventually but making hand sanitiser locally is a great way to fill the gap.”

Watch the multi-head bottling apparatus in action:

9. Testing Wireless Building Sensors

Monitoring and optimising factors such as temperature, energy usage, and occupancy within buildings can play a vital role in minimising energy consumption and carbon emissions, and ensure the comfort and safety of occupants.

In a recent proof-of-concept trial for a new, low-cost approach to building monitoring, we installed 18 wireless sensors throughout PMRC. These sensors acquired data on temperature, humidity, CO2 levels, motion, brightness, door closure contacts, occupancy, and energy usage.

This multi-partner project involving CAE Technology Services, Cisco, ISTL and EnOcean sought to analyse the acquired data and assess the system’s ease of deployment. An essential purpose of PMRC is to support businesses to develop new products and processes, or improve existing ones.

As a result of this trial, we were able to provide feedback and suggest improvements to the system deployment and validate a new, low-cost approach to granular energy monitoring. PMRC occupants were also able to make informed decisions on where energy and carbon savings could be made.

10. People of PMRC

The final number our list, and arguably the best thing about PMRC, is its people. Technicians, researchers, administrators, project support, and industrial partners are all essential to the success of PMRC. Here are some of our favourite staff photos taken at PMRC from the past 10 years.